SES-PRO System

Description

The Lynxmotion Servo Erector Set Professional System (SES PRO) comprises a lineup of powerful and precise modular actuators as well as brackets and connectors used to make anything from a simple winch to a complex multi-degree of freedom robot. The first Servo Erector Set (SES V1) system came out in 2009 and used RC servo motors. The second was released in 2019 and was based around Lynxmotion Smart Servo (LSS) motors and was designed mostly for hobby, research and educational use. One of the goals was to make smart servo technology easy to use; everything from mechanical connections and electronics as well as the simplicity of the communication protocol and software. The professional erector set continues this approach by ensuring the smart servos which form the basis of the system are easy to connect mechanically and electrically, and are controlled using a simple, human-readable communication protocol.

- Continuation of the Servo Erector Set lineup

- Advanced features with minimal complexity

- Daisy chained CAN BUS communication and power

- USB input & direct control

The Lynxmotion PRO actuators are meant to be operated at 30V. This higher voltage means lower current consumption for each actuator. The actuators can be powered by a lab power supply, wall adapter or battery pack (for example an 8 cell Lithium battery pack). Although each actuator has two XT60 connectors, users can use either one for power input (NOT BOTH) and the second connector is meant to allow power to be daisy chained to other actuators in the communication BUS.

| |||||

| Lite Actuator | Standard Actuator | Mega Actuator | Tube Clamp | Carbon Tube | Arm Base |

SES PRO - Mechanics

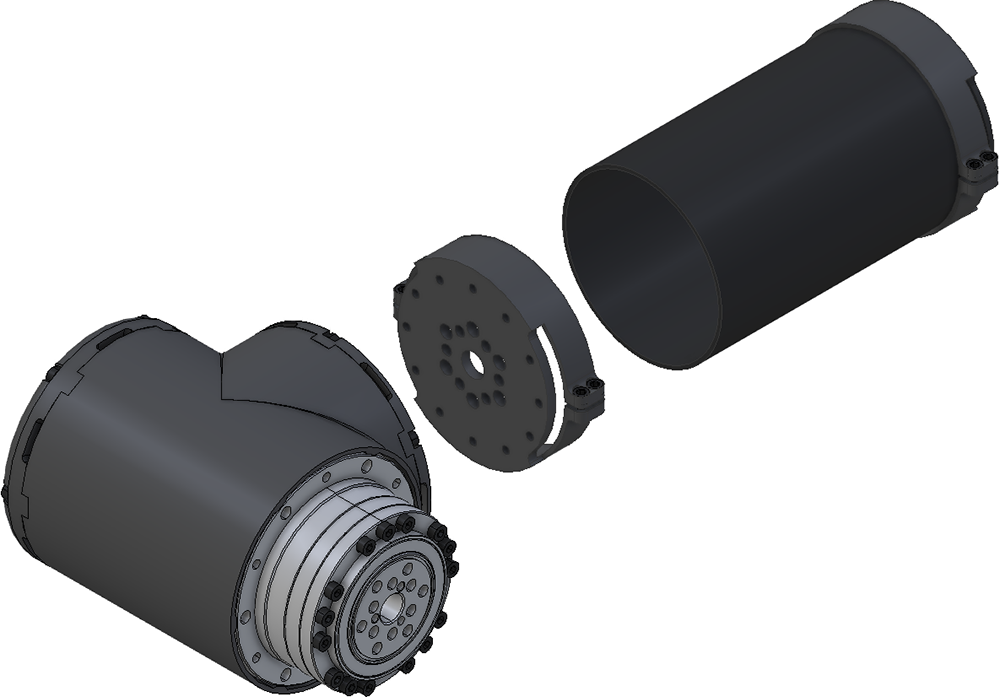

The Lynxmotion PRO actuators and parts use primarily metric dimensions. The servos have two main mounting locations: at the front of each the gearbox, as well as the side plate. Each of the three gearboxes has a distinct mounting pattern, while each of the two side plates have mounting for all three gearbox patterns, as well as a larger pattern for mounting the clamp and other mechanics. The strain wave gear used in each actuator can support high axial and radial loads. The SES-Pro system is not mechanically compatible with the Lynxmotion SESv1 or SESv2 systems. Given the different mounting patterns for each of the three servos, there is no "standard" pattern. Components like the tube clamp include all three mounting patterns, and there is one base for both the LITE and STANDARD servos, but a different model for the MEGA. |

SES PRO - Software

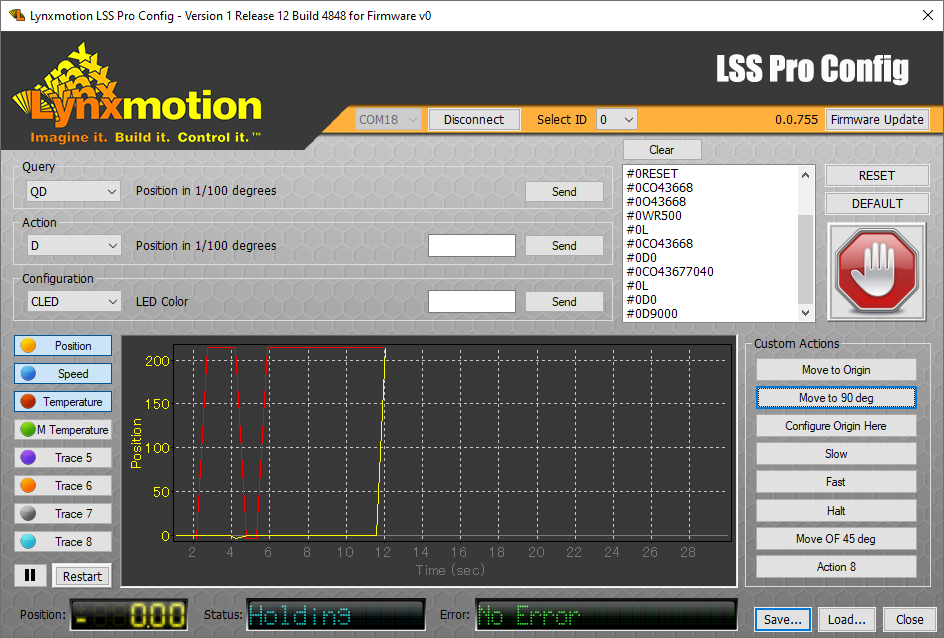

The PRO actuators use a human readable communication protocol. For basic configuration, the LSS PRO Config software allows users to send action and configuration commands as well as queries. Use it to easily assign a unique ID number to each servo before creating an assembly. Libraries for servos are in development, including Arduino, Python and ROS 2. The PRO arms have separate software for motion control and to create sequences. |

SES PRO - Electronics

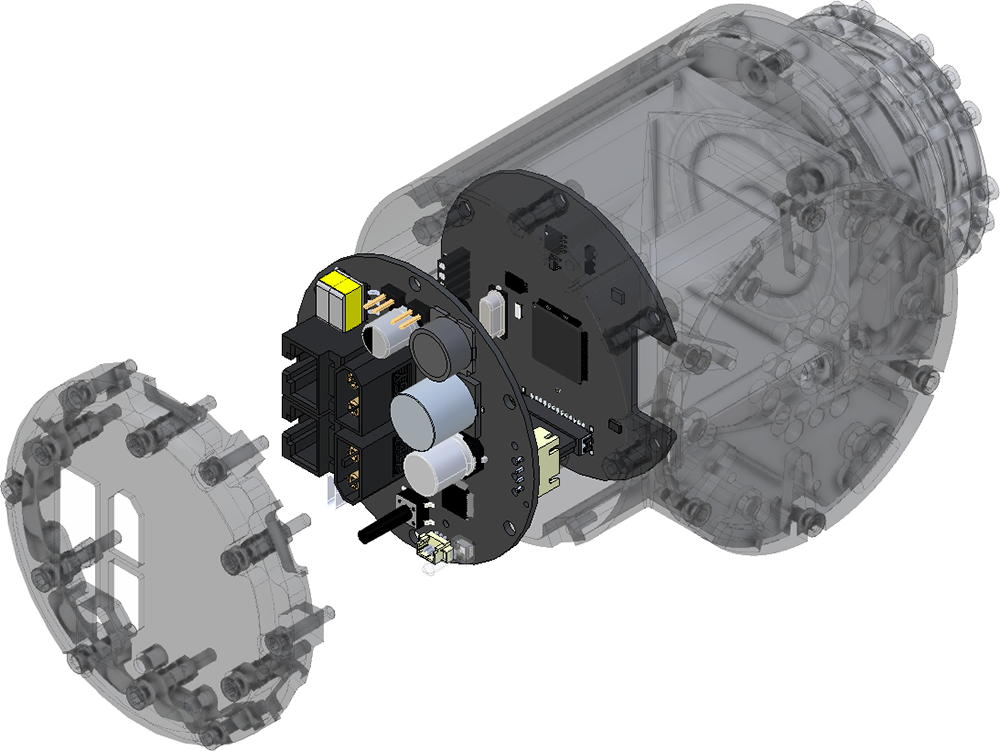

The electronics inside each PRO servo handle all of the features and functions of operating a servo. Inside each actuator is a powerful microcontroller (STM32), an intelligent motor controller, voltage regulation, CAN adaptation, an IMU, encoder and more. Users can control an actuator directly from a USB port, requiring only a separate power source of the correct voltage and current. Daisy chained actuators, assigned Currently the SES-PRO is ideally powered by either the 30V wall adapter or the larger 36V power supply. Options are available from RobotShop, but when selecting a power supply for an application, consider the maximum current draw for each servo and add them up to ensure sufficient current. Note that portable power supplies like 36V lead acid, 10S (37V) Lithium packs can be used (especially for mobile applications), provided their discharge current is sufficient. NOTE: Only ONE power source should be used for each assembly. Connecting two power sources will create issues and potentially damage or destroy everything connected to the system. Additional modules and interfaces may be developed in the future. |