| Wheel

Encoder Assembly Guide. Updated 02/16/2011

Hardware:

- 1 x GH Motor 7.2vdc

50:1 175rpm (6mm shaft) (GHM-04)

- 1 x Quadrature Motor Encoder (QME-01)

Goal:

- Install a wheel encoder on a motor.

Specs:

- GHM-04 motor RPM under load = 7500 rpm

- Encoder = 120 cycles per revolution

- Encoder = 400 quadrature counts per revolution

- Frequency = 30khz |

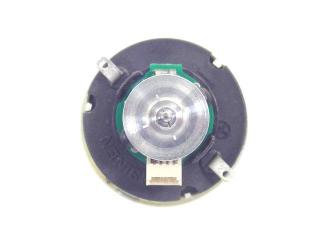

Image of encoder on motor. |

| |

|

|

| |

|

Step

1.

If you going to solder to the motor tabs, it's a good idea to

bend them out of the way before installing the encoder. If you're going to

use push on connectors this step isn't necessary. Be sure to orient the

motor as shown EXACTLY as the raised plastic (name, logo and plus sign)

will prevent the adhesive from making good contact if the encoder is not

applied with the proper orientation. |

Figure 1. |

| |

|

Step

2.

Before removing the adhesive backing material, fit the sensor to the motor

as shown. It has to be oriented EXACTLY as shown for proper fit. When you

are happy with the placement, remove the backing and carefully press it in

place. I have not needed the expensive alignment tool from US Digital to

do this, but you have to be careful not to press it firmly until it is

exactly centered. If you are good with your hands this will be easy. If

you have ten thumbs, you might want to ask for help. |

Figure 2. |

| |

|

Step

3.

Simply press the encoder disk onto the motor shaft. Press it down firmly

and this step is complete. |

Figure 3. |

| |

|

Step

4.

Snap on the top plastic part. |

Figure 4. |

| |

|

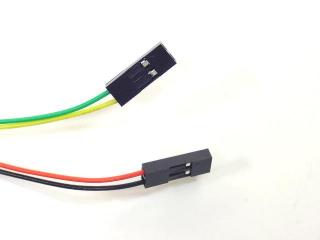

Step

5.

Insert the cable as shown. |

Figure 5.

|

| |

|

Step

6.

Red = +5vdc

Black = Ground

Green = Output A

Yellow = Output B |

Figure 6. |