Quadruped QBK-02 Symmetric Robot Kit Assembly Instructions Rev. 1

| QBK-02 Symmetric

Quadruped Robot Kit Assembly Instructions Rev. 1.

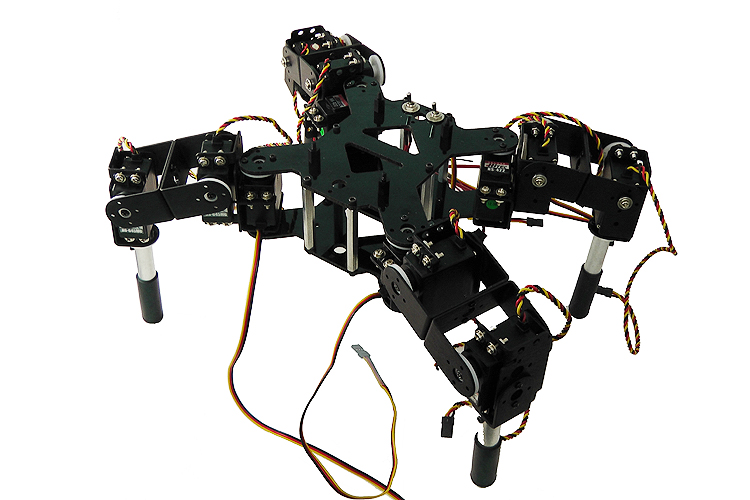

Updated December 2014 Safety first! Wear eye protection and never touch a powered robot! The purpose of this guide is to construct the chassis, attach the legs, and install the electronics. Both the top and bottom body plates are identical. This guide shows the Lynxmotion PS2 and PS2 mounting plate which are purchased separately from the kit (used only with BotBoarduino version). There are the following SQ3 kits:

Take note of which version you have

and follow each step accordingly, as the connections and configuration

are different. Note: Loctite / thread lock can be used on the construction of the aluminum components, though it is not necessary if the nuts are properly tightened. However, don't use thread lock with Lexan or plastic, as they are not necessary and may cause damage. |

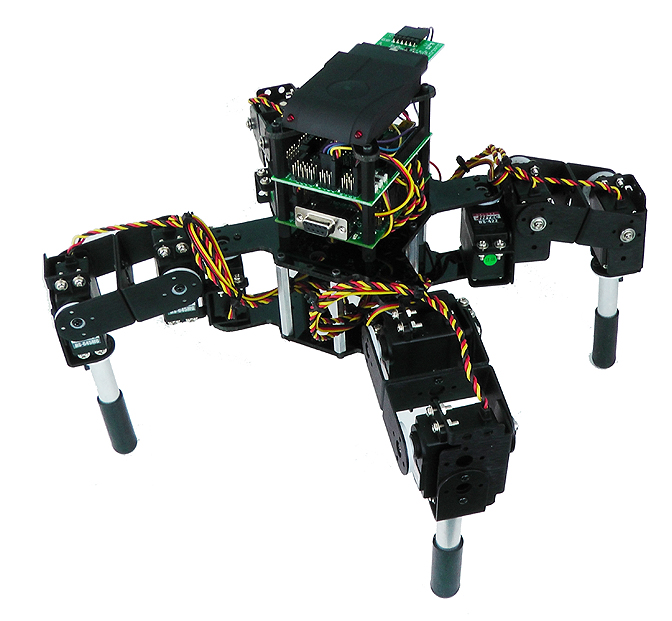

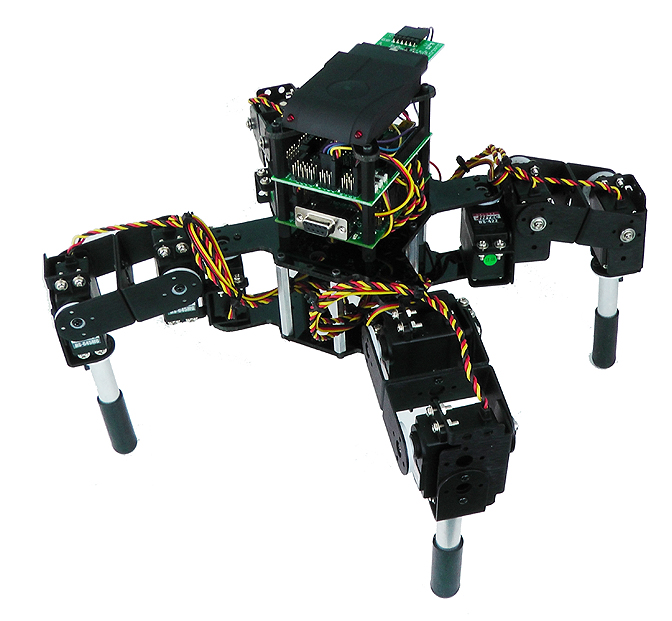

Image of completed Robot. (Shown with optional PS2 receiver and mount) |

||||

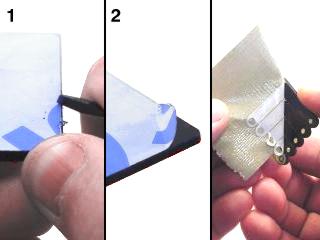

| Lexan

Preparation. The lexan pieces have a protective covering that needs to be removed before assembly. When the laser cuts, the covering melts into the cut edge which can make removal difficult. If you gently scrape the cut edge with a flat blade screwdriver, the covering can easily be lifted and peeled off. On smaller pieces the coverings can be more difficult to remove. If you have trouble you can gently scrape the cut edge, then use duct tape to lift the covering off. For further information on lexan, see this page. |

|

||||

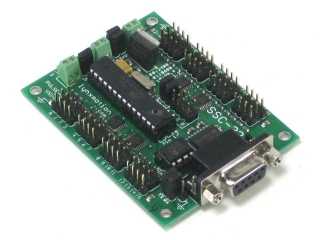

| Step 1.

Electronics User Guides If you have the SSC-32 serial servo controller, please read through and understand the SSC-32 User Guide. If you have the SSC-32U USB servo controller, please read through and understand the SSC-32U User Guide. If you purchase the version with the BotBoarduino, read and understand the BotBoarduino User Guide. The QBK-02 uses the arduino software downloadable from www.arduino.cc. This guide does not teach you how to use the Arduino programming language. |

Figure 1 (SSC-32 Shown as example) |

||||

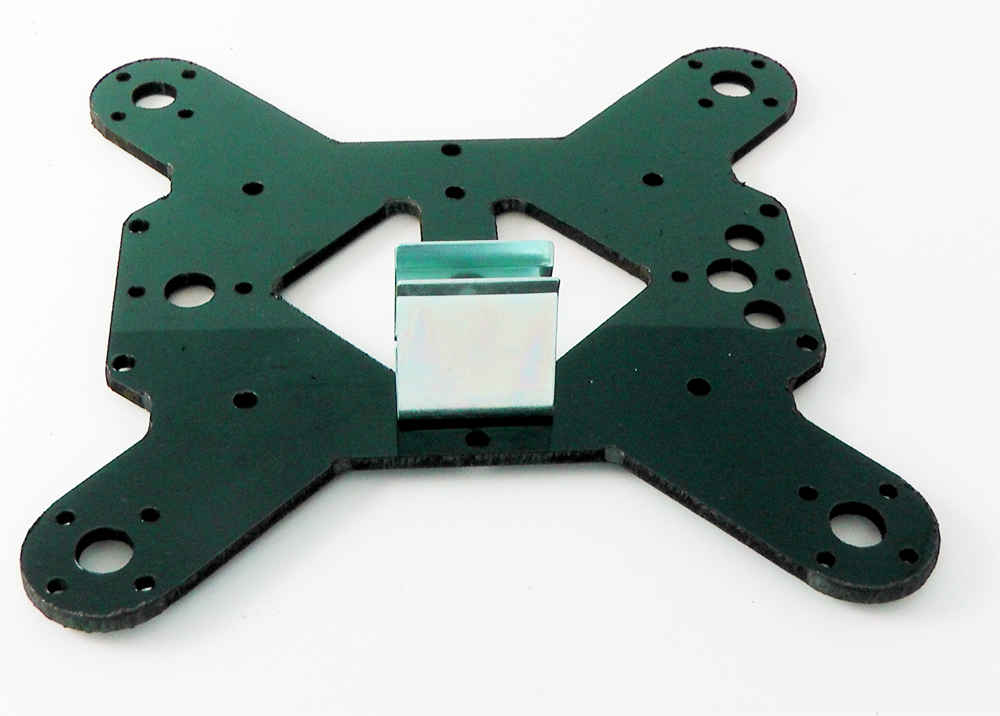

| Step 2

(BotBoarduino and/or SSC-32). If you have the SSC-32 (not SSC-32U) or a kit which uses the BotBoarduino, the robot will need a separate 9V battery. Both the top plate and bottom plates are identical. Place the small black rivet through the 9V metal clip and push down through one of the two inner holes as shown. It does not matter which side. This will become the bottom plate.

|

Figure 2 (SSC-32 and/or BotBoarduino) |

||||

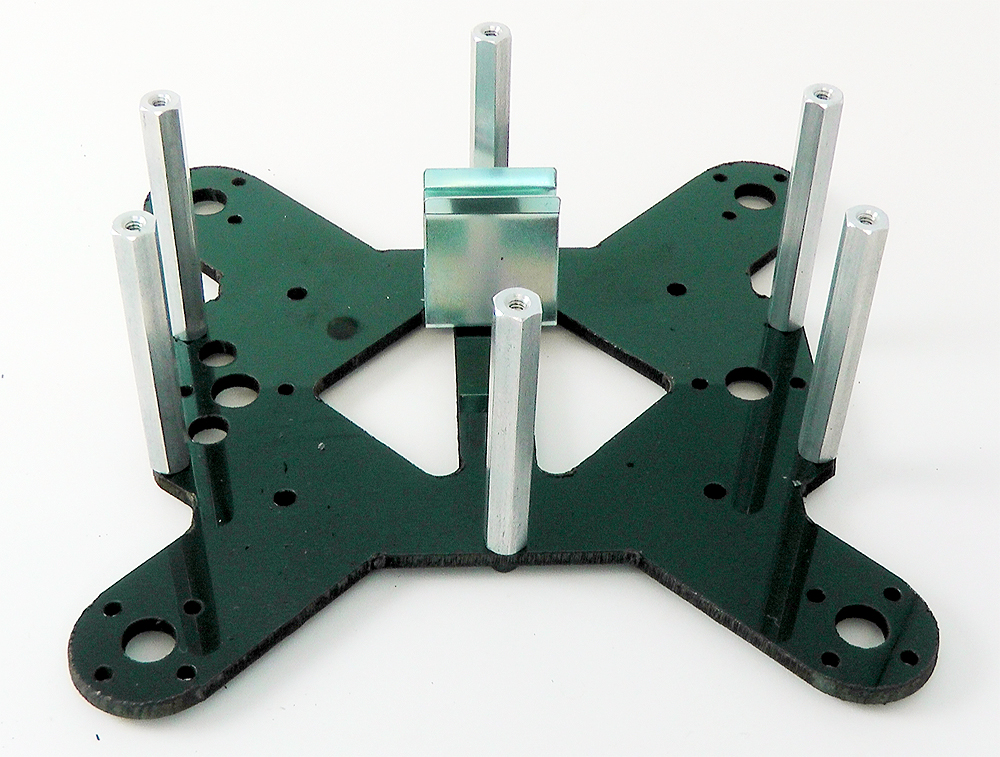

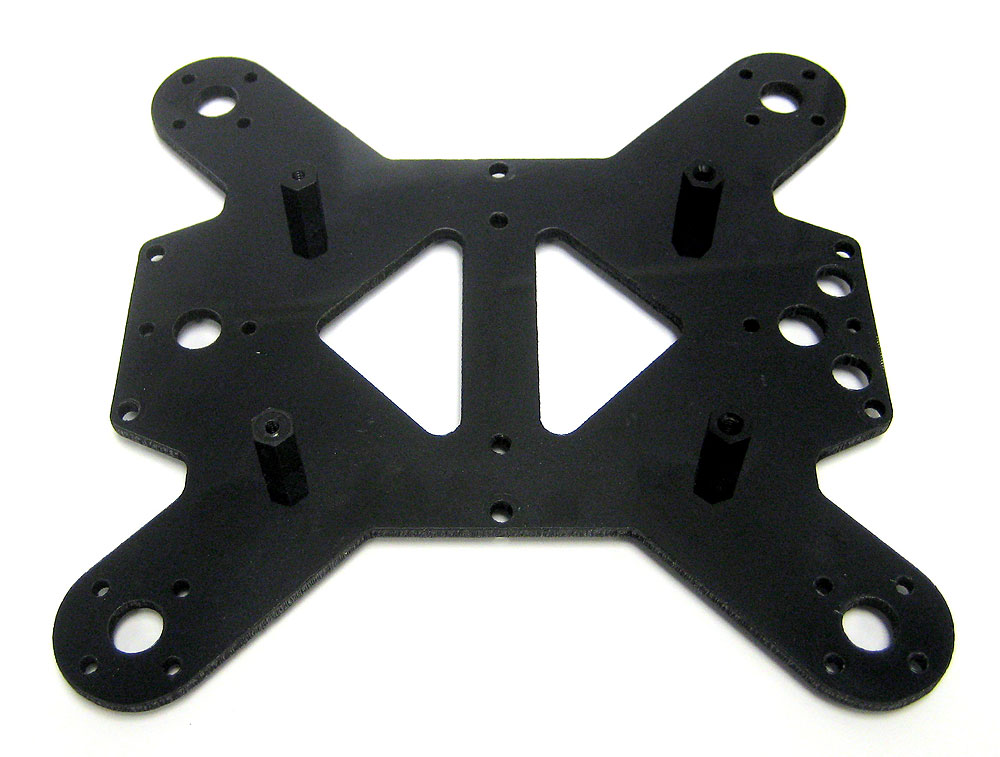

| Step 3a (SSC-32 and/or BotBoarduino). Use six 4-40 x 1/4" hex socket screws to attach the long aluminum spacers to the bottom body plate.

|

Figure 3a (SSC-32 and/or BotBoarduino). |

||||

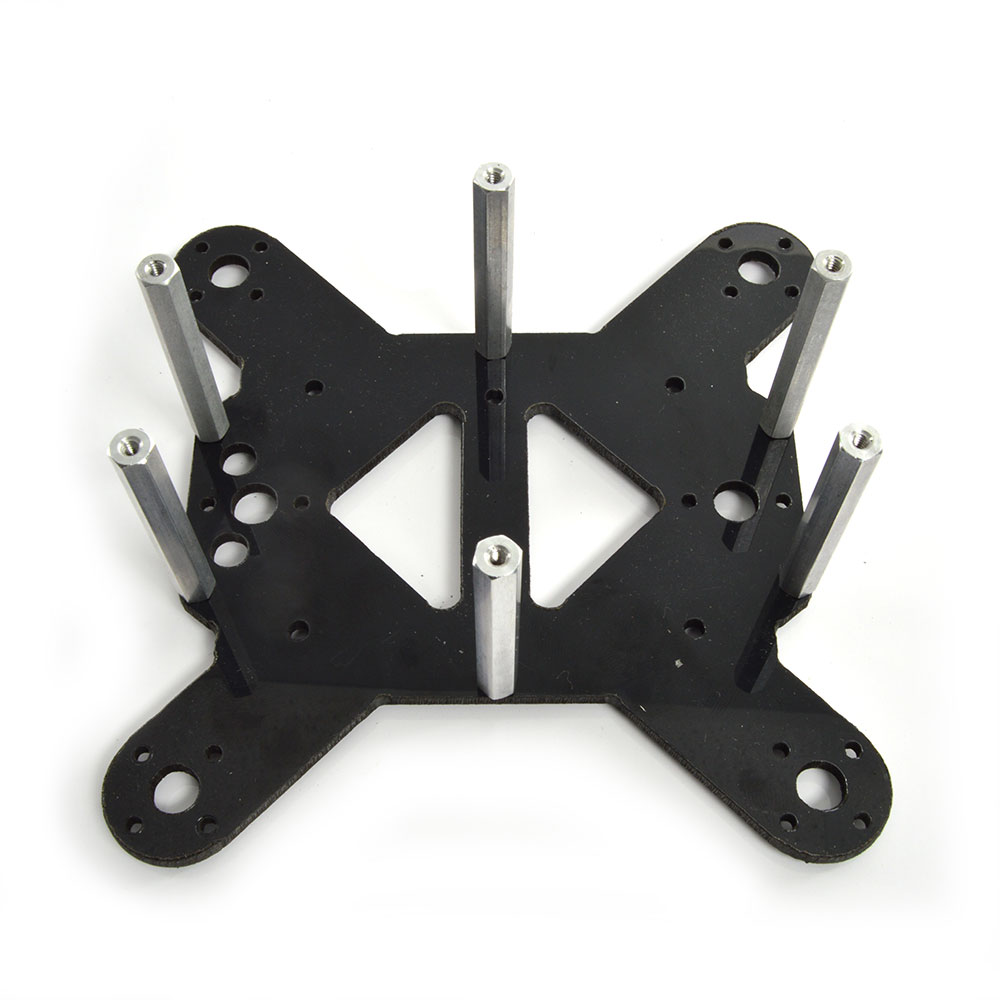

| Step 3b (SSC-32U Alone). Use six 4-40 x 1/4" hex socket screws to attach the long aluminum spacers to the bottom body plate. Since the SSC-32U does not need a separate 9V battery, the 9V metal clip is not needed.

|

Figure 3b (SSC-32U Alone). |

||||

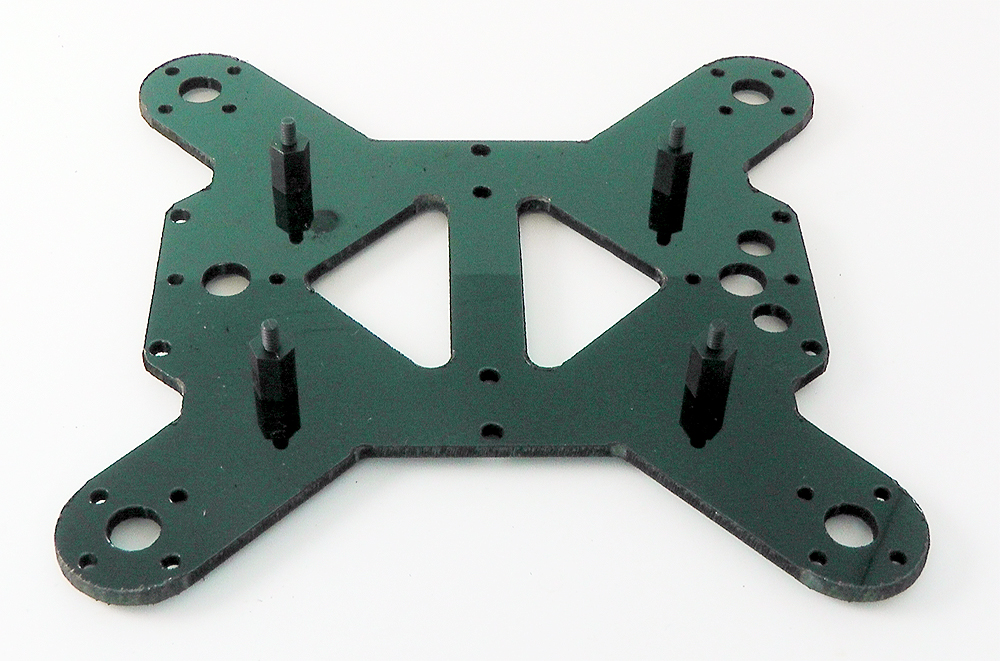

| Step 4a (BotBoarduino). If you purchased any kit which includes the BotBoarduino, follow this step, otherwise proceed to step 4b. Use the second (top) plate for this step. Use four 4-40 x 1/4" hex socket screws to attach the 1/4" long M/F plastic spacers to the plate. The M/F spacer is required because the electronics (SSC-32 / 32U) and the BotBoarduino will be stacked one on top of the other.

|

Figure 3 (M/F Spacer for BotBoarduino). |

||||

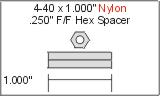

| Step 4b (SSC-32 or SSC-32U alone). If you purchased a kit with FlowBotics Studio (and therefore do not have a BotBoarduino), follow this step. Use the second (top) plate for this step. Use four 4-40 x 1/4" hex socket screws to attach the 1/4" long F/F plastic spacers to the plate. This F/F spacer is used because there will not be any additional electronics stacked above the servo controller.

|

Figure 3 (F/F Spacer for BotBoarduino). |

||||

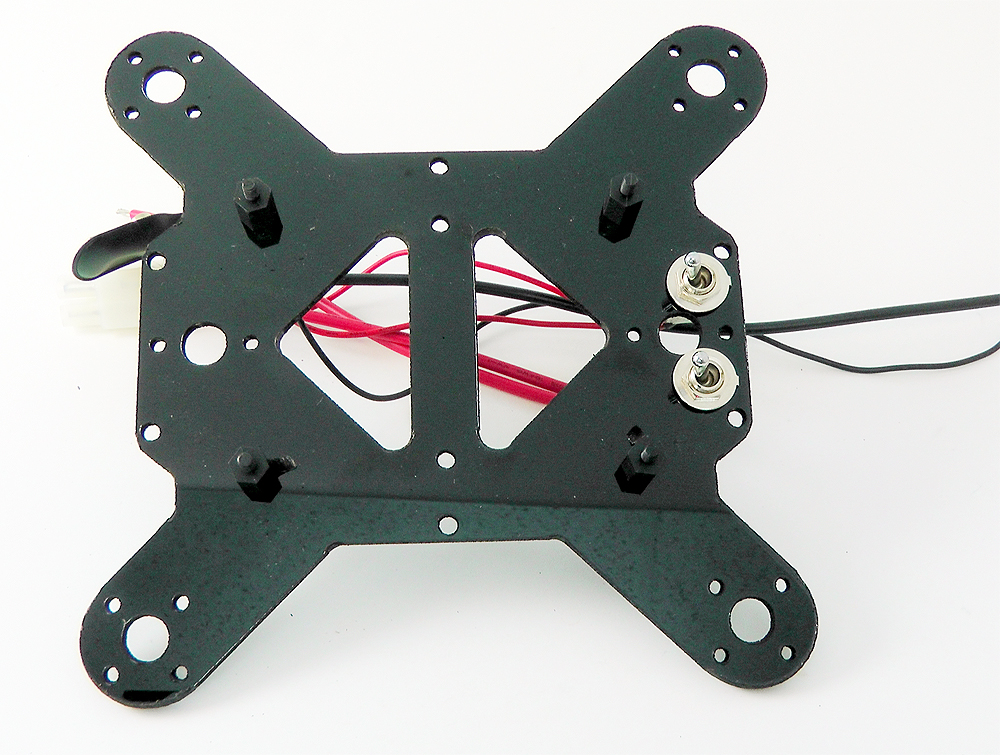

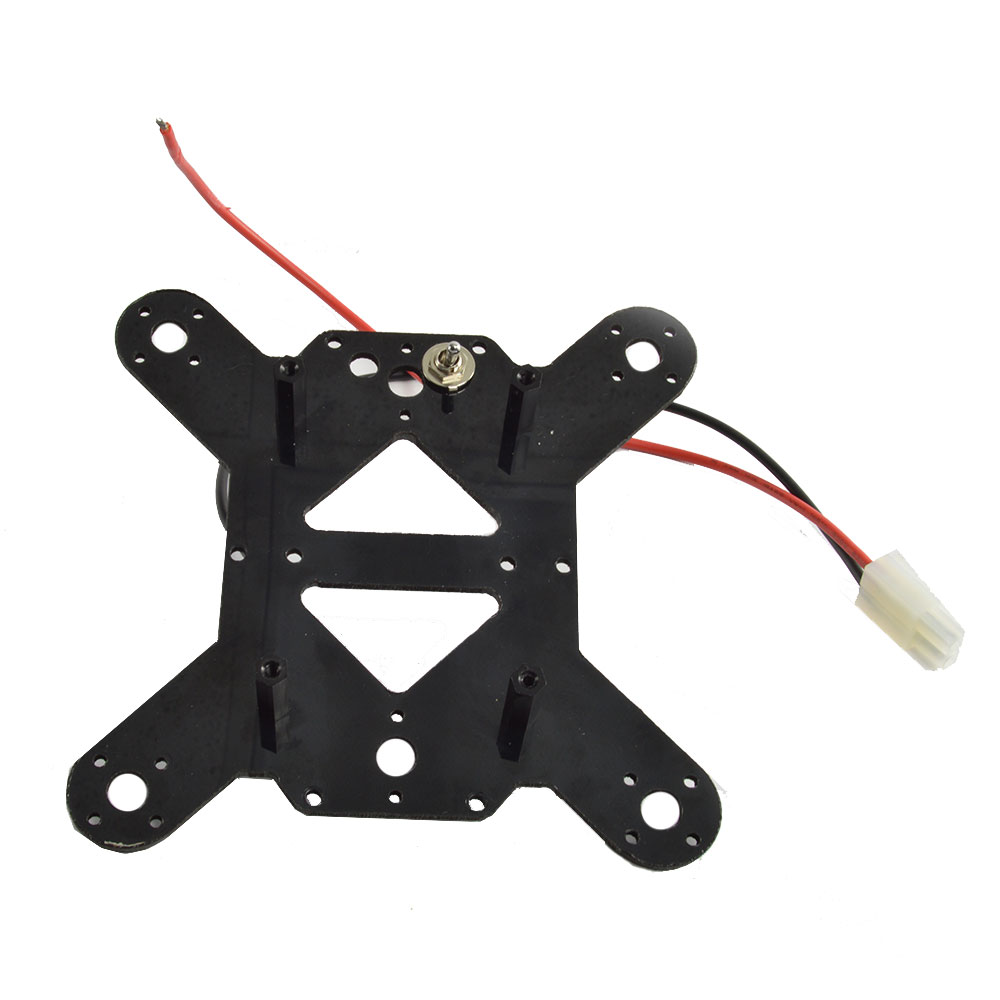

| Step 4a (SSC-32 and/or BotBoarduino). Connect the 9V wiring harness and the servo (Tamiya) battery harness to the top plate. It does not matter which switch connects to which hole. The SSC-32U does not need the additional 9V wiring harness. |

Figure 4a (SSC-32 and/or BotBoarduino). |

||||

| Step 4b (SSC-32U). Connect only the battery harness to the top plate. It does not matter which hole you use. Note that the 9V wiring harness is not needed for the SSC-32U alone, so it is not included. |

Figure 4b (SSC-32U). |

||||

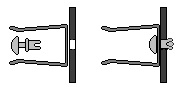

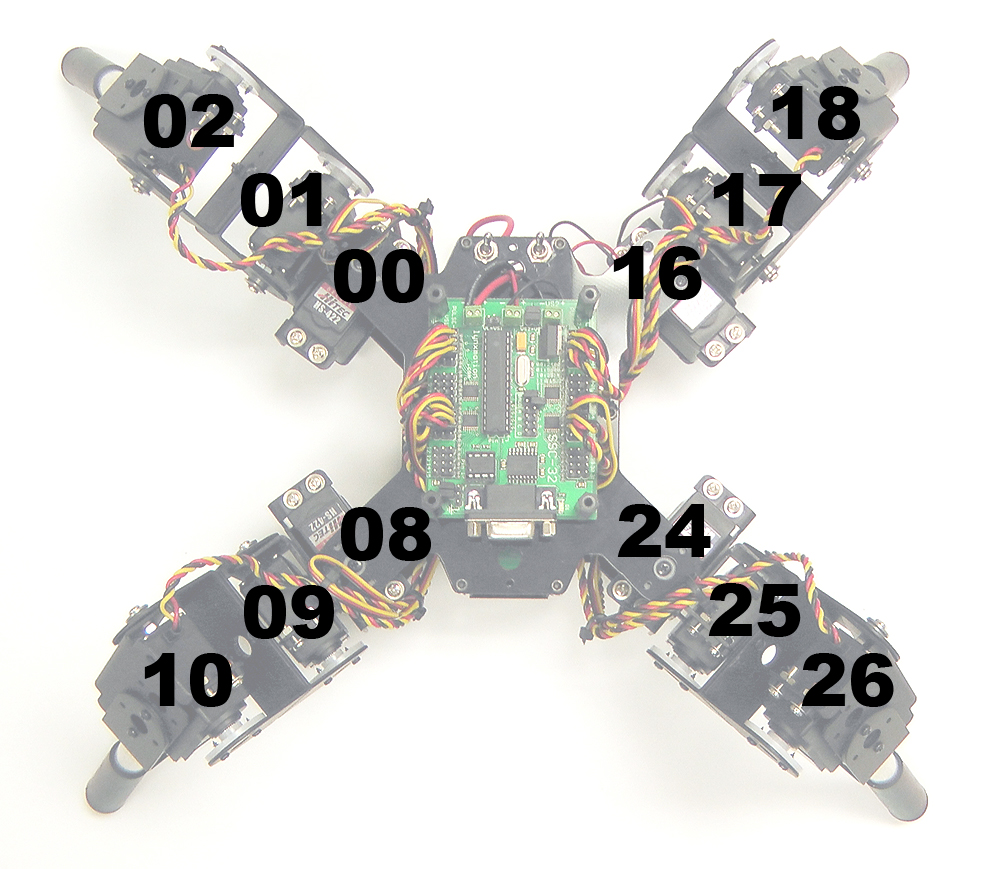

| Step 5. Attach the legs as shown, making sure to use right / left legs as indicated. Figure 7c shows a top-down view. Note the symmetry along both axes (left side is a mirror of the right side). Use eight #2 x .250" tapping screws (two per servo). The "rear" of the robot has the circular cutouts for the power connectors. The legs should be at 45 degrees when the servo receives a 1500us pulse (legs at 90 degrees to each other as in figure 7c). If you are unsude how to do this, please refer back to the leg assembly guide.

|

Figure 5. |

||||

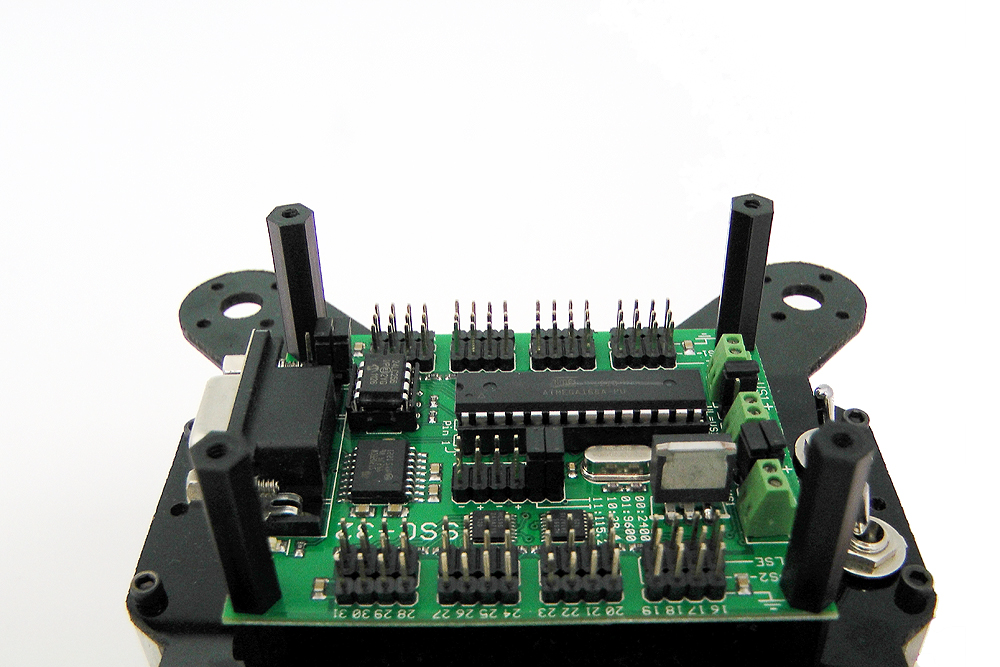

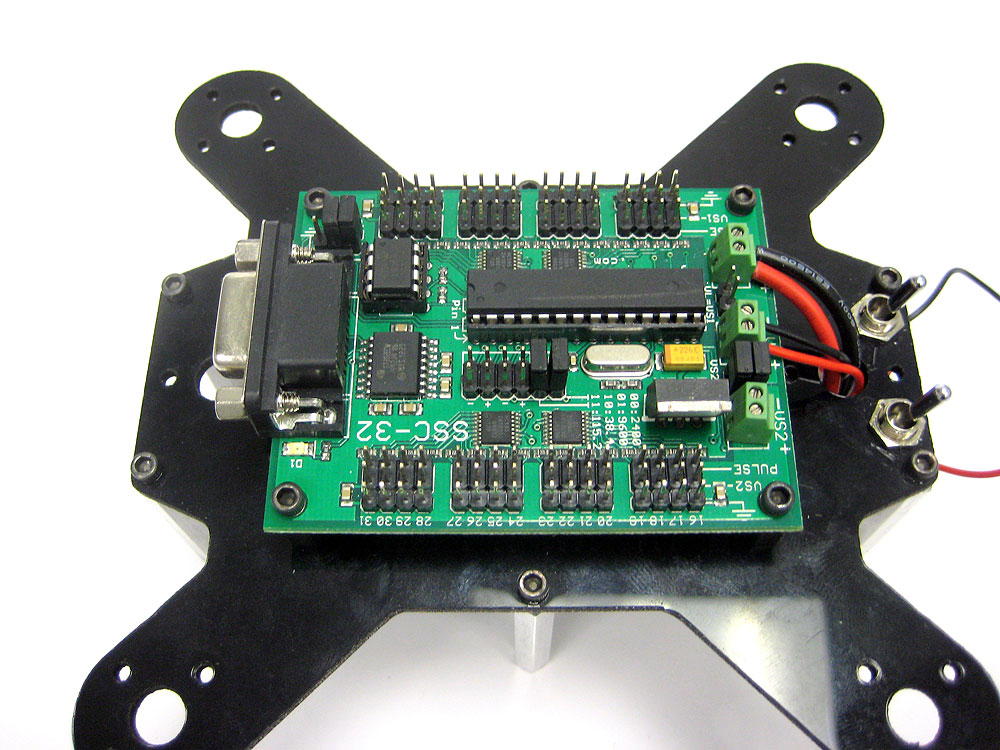

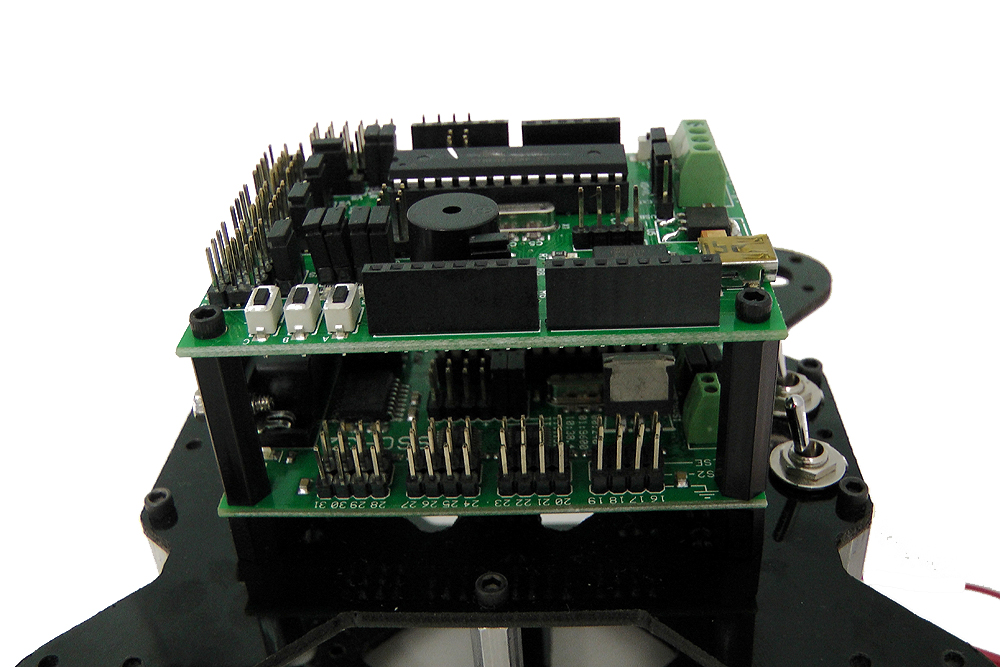

| Step 6a (BotBoarduino).

Mount the SSC-32 / SSC-32U onto the four hex spacers installed in step 4a. Orient the board with the SSC-32's connector facing the front of the robot (so as to not interfere with the switches). Use four 4-40 x 1" hex spacers to attach the long aluminum spacers to the underside of the top body plate. These new spacers will be used to support the BotBoarduino. If you purchased or have the optional PS2 expansion plate, use the four 1" M/F standoffs included with that kit. Wiring will be explained in the next steps.

|

Figure 6a (Kits w/BotBoarduino). |

||||

| Step 6b (FlowBotics). If you have a version of a kit which only has a servo controller (ex FlowBotics kits), mount the SSC-32 / SSC-32U onto the four hex spacers installed in step 4b. Use four 4-40 x 1" hex spacers to attach the long aluminum spacers to the underside of the top body plate.Wiring will be explained in the next steps.

|

Figure 6b (SSC-32 or SSC-32U). |

||||

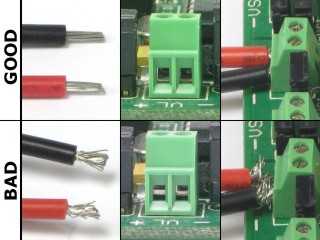

| Step 6. In preparation for connecting the wires, here are some general guidelines when inserting wires into the screw terminals. Use a ~2mm wide flat blade screw driver. Rotate the screw both directions looking into the end of the terminal. When you see it open up (moving downwards), keep turning until it is open completely. Wrap / twist the wires by hand to ensure they are aligned as in Figure 6. Be sure that the wires are fully inserted into the terminals and that no stray wires touch each other between terminals as this is a short and can cause the battery to discharge rapidly, causing heat and possibly fire. DOUBLE CHECK THE RED AND BLACK WIRE CONNECTED TO THE SCREW TERMINALS - the red wire should go to (+) and the black wire to (-), if they are reversed, the servos and the board will be damaged.

|

Figure 6 (top shows open screw terminal, bottom shows closed). |

||||

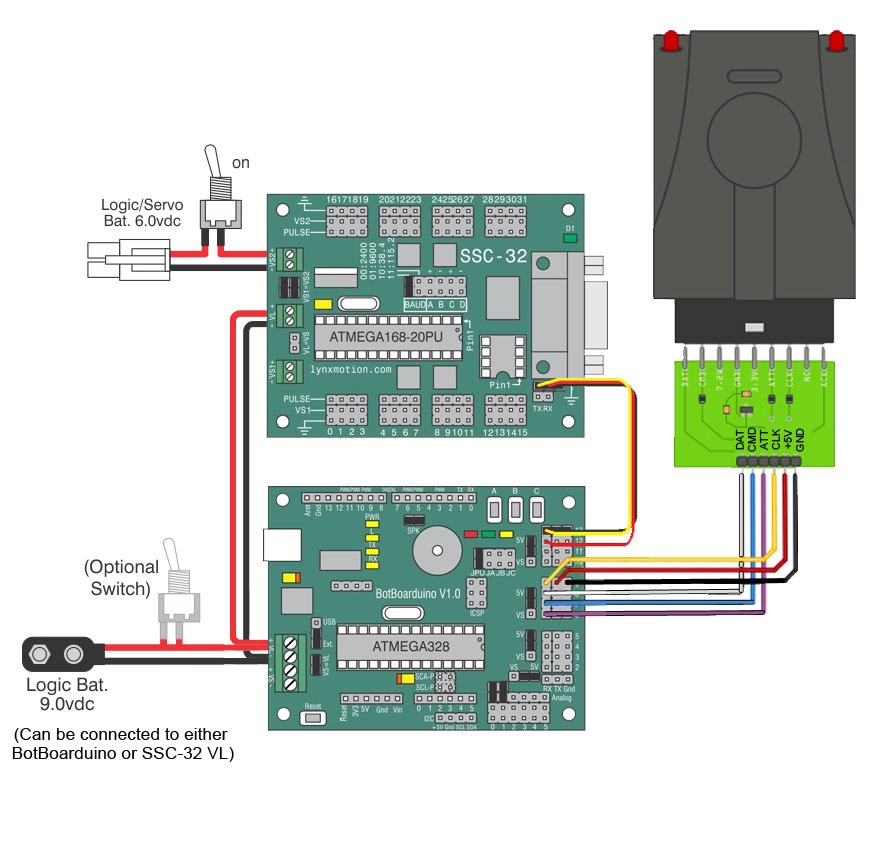

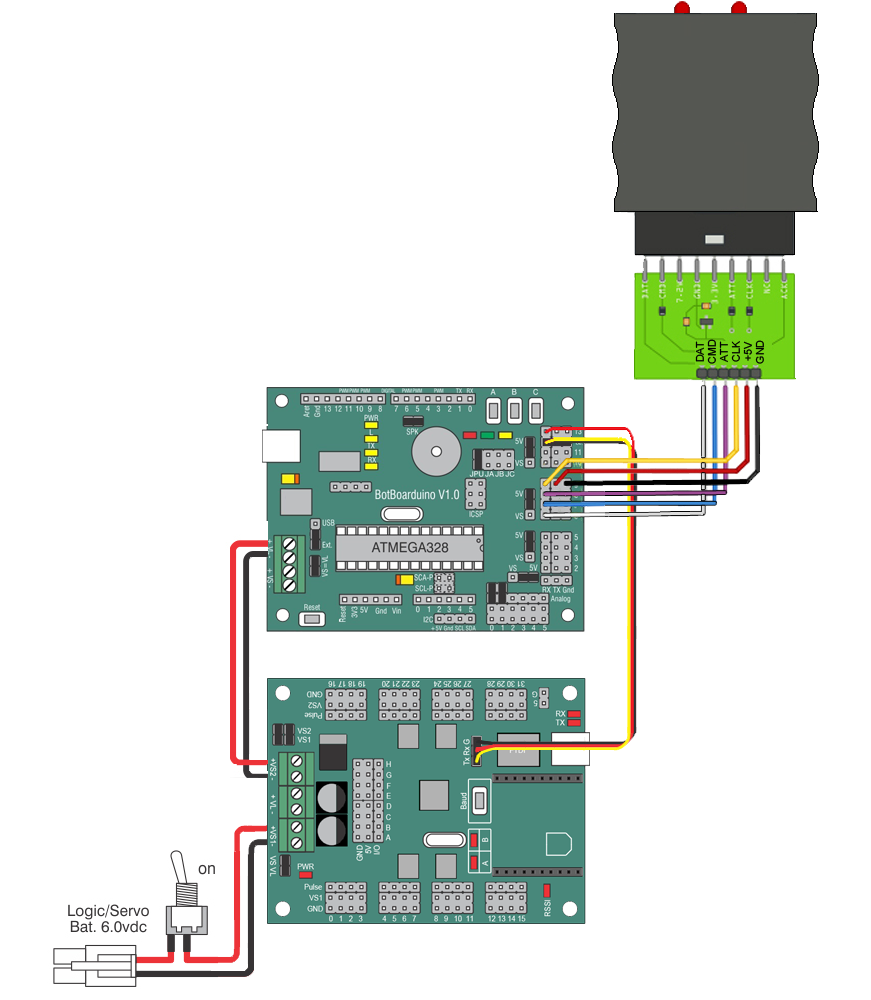

Step 7a (BotBoarduino + SSC-32 + PS2 v2).

This

step applies if you purchased the BotBoarduino version of the SQ3 with

the SSC-32 serial servo controller. The PS2 controller is optional (PS2

mounting plate suggested). Attach the power cables as shown in Figure

7a. Connect the servos to the SSC-32; refer to step 8 and 9

below. Once all servos have been connected (having followed steps 8 and

9), connect the loose power cable from the SSC-32's VL terminal to the

BotBoarduino's VL terminal. We suggest wiring everything with the

BotBoarduno loose, and only attaching it to the spacers at a later

step. DOUBLE CHECK THE RED AND BLACK WIRE

CONNECTED TO THE SCREW TERMINALS - the red wire should go to (+)

and the black wire to (-), if they are reversed, the servos and the

board will be damaged.

Figure 7a.

BotBoarduino - SSC-32 - PS2 v2

Step 7b (BotBoarduino + SSC-32U + PS2 v2/3).

This step applies if you purchased the BotBoarduino version of the SQ3 with the SSC-32U USB servo controller. The PS2 controller is optional. Install the SSC-32U onto the body onto the standoffs shown in step 4, and secure using four 1/4" 4-40 hex standoffs.

Connect the serial to XBee breakout board's positive pin to pin C (+)

on the SSC-32 and the negative pin to pin D (-) on the SSC-32. Notice

the Baud rate jumper is set to 9600. You can install the power

switch(es) to the body in the holes at the rear of the robot. DOUBLE

CHECK THE RED AND BLACK WIRE CONNECTED TO THE SCREW TERMINALS

- the

red wire should go to (+) and the black wire to (-), if they are

reversed, the servos and the board will be damaged. Change the jumper

located behind the screw terminals to EXT rather than USB (so the logic

voltage is powered via the 9V battery rather than the USB cable).

Remove the VL=VS jumper.

Figure 7b. BotBoarduino - SSC-32U - PS2 v3

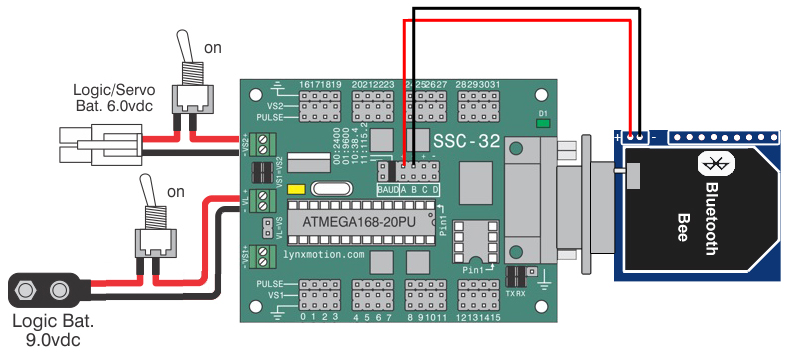

Step 7c (SSC-32 + Bluetooth).

This

approach applies if you plan to control the robot

from the computer using a Bluetooth device (as is the case with

FlowBotics Studio). Attach the power cables as shown in Figure 7b.

Install the SSC-32 onto the body using four 1/4" x 4-40 hex screws.

Connect the serial to XBee breakout board's positive pin to pin C (+)

on the SSC-32 and the negative pin to pin D (-) on the SSC-32. Remove

the Baud jumper to set the Baud rate to 9600. You can install the power

switch(es) to the body in the holes at the rear of the robot. DOUBLE

CHECK THE RED AND BLACK WIRE CONNECTED TO THE SCREW TERMINALS - the

red wire should go to (+) and the black wire to (-), if they are

reversed, the servos and the board will be damaged.

Figure 7c. SSC-32

- Bluetooth

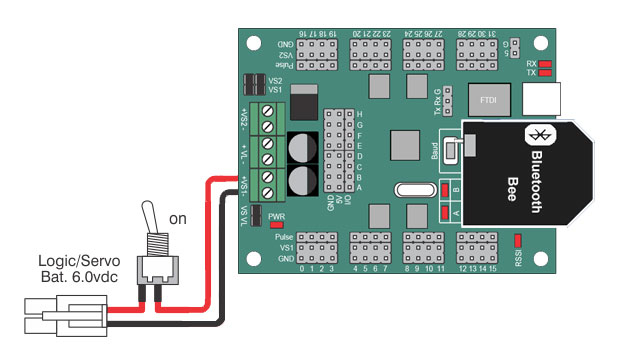

Step 7d (SSC-32U + Bluetooth).

This approach applies if you plan to control the robot

from the computer using a Bluetooth device (as is the case with

FlowBotics Studio). Attach the power cables as shown in Figure 7b.

Install the SSC-32 onto the body using four 1/4" x 4-40 hex screws.

Connect the serial to XBee breakout board's positive pin to pin C (+)

on the SSC-32 and the negative pin to pin D (-) on the SSC-32. The power

switch(es) should be connected to the body using the holes at the rear of the robot. DOUBLE

CHECK THE RED AND BLACK WIRE CONNECTED TO THE SCREW TERMINALS - the

red wire should go to (+) and the black wire to (-), if they are

reversed, the servos and the board will be damaged.

Figure 7d. SSC-32U - Bluetooth

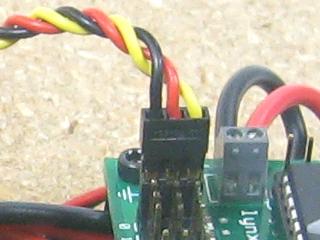

| Step 8. Plug the servos into the SSC-32 as shown in figure 9 with the yellow signal wire towards the inside of the board. Simply plug in the servo associated with the function to the corresponding pin (see step 9). Once again, be sure the black wire is near the outside of the board and the yellow wire is near the center of the board as shown in figure 8. Proper cable routing can be done later. |

Figure 8. |

||

|

Step 9.

|

|||

| Step 10 (SSC-32 and/or BotBoarduino).

If you have a kit with an SSC-32 and/or BotBoarduino, connect a fresh / charged 9v battery to the battery clip to power the electronics and turn the On/Off switch to On. You should see the green LED in the upper right corner of the SSC-32 switch on. There is also a power LED on the BotBoarduino. If you have an SSC-32U alone, turn On the switch to power (and test) the board. If these LEDs do not switch on, IMMEDIATELY power off your robot and double check your connections. Turn this switch off. |

|||

| Step 11a (SSC-32 and/or BotBoarduino). Connect the 6V battery pack to the battery harness to power the servos. Flip the switch to turn the servo power on. The LEDs should NOT switch on this time (since the logic switch to the 9V battery is off). If they do turn ON, immediately power off your robot and double check your connections. Note, our

battery packs do NOT come charged. You will need to charge your battery

before proceeding to the next tutorial. |

Figure 11. |

||

| Step 11b (SSC-32U). Connect the 6V battery pack to the battery harness to power the servos. Flip the switch to turn the servo power (the switch to the 9V battery should be OFF). The LEDs should NOT switch on (since the logic switch to the 9V battery is off). If they do turn ON, immediately power off your robot and double check your connections. If they did not turn on, now turn off the servo power and thrn on the logic power (9V). The LEDs should turn on, and the servos should not move. Note, our battery packs do NOT come charged. You will need to charge your battery before proceeding to the next tutorial. |

|||

| Step 12 (BotBoarduino). If your kit includes a BotBoarduino, use four 4-40 x 1/4" hex socket screws to mount the BotBoarduino to the hex spacers in the orientation shown, on top of the SSC-32. The figure does not show the wiring for clarity. If you have the optional PS2 mounting plate, follow those guidelines for assembly. Be sure to have the

|

Figure 12. Mount the BotBoarduino (wires removed for clarity) |

||

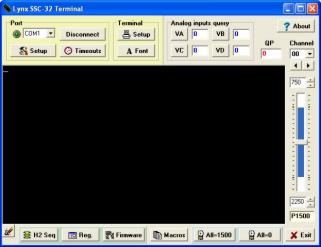

| Step 13a (SSC-32). It is likely that when you assembled the legs, the positions were not exactly at 90 degrees (though be sure to get them as close as you can). You have two options to fine tune the angle of each of the servos, the first of which is to use the old Lynxterm software. Download and install Lynxterm. Lynxterm needs a physical connection to the computer and as such cannot use the Bluetooth module. If your computer does not have a serial port, you will need a serial to USB adapter. Disconnect the SSC-32 from the BotBoarduino and reinstall the Tx / Rx jumpers, as well as both Baud jumpers (so the baud rate is at 115200). Power the SSC-32 (both VL and VS), open Lynxterm, select the correct COM port and click "All=1500". The servos should all move to 90 degrees. Next, click "Reg." and in the new window, click "Read". Position each servo to exactly 90 degrees by using either the slider or by typing in the offset (changing the Channel at the right of the window for each servo used). Once this is done, click "Write", which then modified the firmware on the SSC-32. |

Figure 13a. Lynxterm |

||

| Step 13c (SSC-32U). If you have the SSC-32U alone, you can calibrate / fine tune each joint using the SSC-32 Servo Sequencer Utility (download and install). Note that fora quadruped to walk properly, the legs must be close to perfectly tuned. Connect the SSC-32U to the computer via USB (if you have the Bluetooth module installed, you can connect via Bluetooth; the green light on the Bluetooth will become solid once a connection has been established). By default, only four servos are active within the utility software. Check off all servos marked in figure 7c within the software in order to activate them. Click the "configure" button towards the bottom right of the window and a knob will appear next to each servo. To position each of the servos to exactly 90 degrees, click the knob and drag it up and down to offset that servo's position. Do this for each servo until their position is exactly at 90 degrees. Once all servos have been adjusted to correct any small mechanical offset, press "calibrate" once again and the ofsets will be saved to the board. The servo calibration can also be done via FlowBotics Studio, though the calibration is saved on the specific computer as opposed to the SSC-32U. |

Figure 14 (SSC-32 Utility). |

||

| Step 14. The robot should now be wired and calibrated correctly, but with wires going everywhere. It is now a matter of cleanly routing the cables. You can unplug and re-plug the wires as needed, especially for the servos, and well as run them through the body and brackets. Be certain to reconnect the correctly and leave enough length so each joint in the legs are able to move freely and reach all positions and do not get pinched by the brackets or servos. Use the cable ties provided in the kit to connect the wires together. Alternatively, black electrical tape or wire wrap also look nice. Ensure the main 6V battery is perfectly centered inside the body to ensure the robot walks properly. |

Figure 14 (Optional PS2 receiver and PS2 mounting plate) |

||

| Step 15. If you purchase a kit which uses the BotBoarduino, sample code (based on PS2 control) can be found here. If you have difficulties installing the library or code, please refer to www.arduino.cc for additional information. If you purchased a kit which uses FlowBotics Studio, you can install and run FlowBotics Studio and open the quadruped project. |

|||