Direct-Drive Parallelogram 2DoF Leg Pair Assembly Guide

| Aluminum Direct-Drive Parallelogram 2DOF Leg Pair Assembly Guide.

Updated 08/30/2007

Hardware: Goal: |

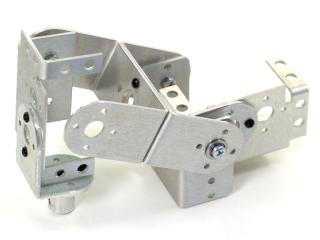

Image of DDP 2DOF Leg. |

|

|

|

| Step 1. Attach an "L" connector bracket to a Multi-Purpose bracket as shown, using two 2-56 x .250 screws and 2-56 nuts. 2 x |

Figure 1. |

| Step 2. Attach a Passive Hinge bracket to the "L" bracket as shown, using two 2-56 x .250 screws and 2-56 nuts. 2 x |

Figure 2. |

| Step 3. Attach the ball bearing that comes with the Long "C" bracket to the Multi-Purpose bracket as shown. See the diagram below for detailed information.

|

Figure 3-2. |

| Step 4. Attach the "C" bracket to the Passive Hinge bracket as shown, using two ball bearings. See the diagram below for detailed information.

|

Figure 4-2. |

| Step 5. Attach another "C" bracket to the "C" bracket already there, using two 2-56 x .250 screws and 2-56 nuts. 2 x |

|

| Step 6. Attach the "C" bracket to a Multi-Purpose bracket as shown. See the diagram below for detailed information.

|

|

| Step 7. Attach a Tubing Connector Hub to an "L" bracket as shown, using two 2-56 x .250 screws and 2-56 nuts. 2 x |

|

| Step 8. Attach the other side of the "L" connector bracket to the Multi-Purpose bracket as shown, using two 2-56 x .250 screws and 2-56 nuts. 2 x |

Figure 8. |

| Step 9. Connect a 3.0" tube to the hub using a 4-40 x .250" screw. Attach a rubber foot to the end of the tube. 1 x |

Figure 9-2. |

| Step 10. Use 1.5" of 4-40 threaded rod to make a "dog bone" with a black plastic socket at each end. Attach the dog bone to the Multi-Purpose bracket and the Passive Hinge bracket as shown. See the diagram below for detailed information.

|

Figure 10-2. |

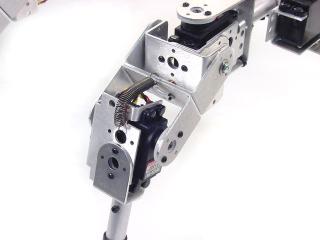

| Step 11. Install the servos as shown, using the included 3mm hardware, and two #2 tapping screws. For quick prototype assembly, you can use rivet fasteners (sold separately: NSRF-01) as illustrated. 2 x |

|

| Step 12. You can adjust the angle of the leg by changing the length of the dog bone. |

|

| Step 13. By adding a spring, the joint can be load-balanced. This is a trade-off because when the leg is in the Down position, the load on the servo is reduced. However, the load when the leg is in the Up position is increased. |

|

| Step 14. Now the leg is ready to be attached to a body. Use two #2 tapping screws. These parts are included in the lexan chassis kits or the Long "C" brackets for an aluminum chassis. 2 x |

|