Hexapod Foot Sensor Assembly Guide

| Hexapod Foot Sensor Assembly Guide. By James Frye Updated 02/14/2008. This tutorial will guide you through the process of building and setting up your Hexapod Foot Sensor. The sensor used is a Force Sensing Resistor, FSR for short. The kit includes two FSRs, hexapod foot caps, rubber bumpers, and hubs. You will need to provide the following: o Electrical tape. Note, this kit is compatible with the AH3-R and 3DOFA legs (BRU/BLK). |

Image of included components. |

| Step 1. Solder some 24 gauge or lighter wires onto the force sensors as shown. Cover the connections with heat shrink. Note, the wires will need to have enough slack to not bind the legs while the robot is walking. It's best to be generous with the wire at first - you can always trim the wires after everything's in place. |

Figure 1. |

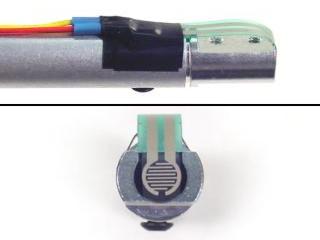

| Step 2. Attach the tubing hub to the tubing using a button head screw as shown. Note, if your hubs include additional 4-40 socket head cap screws, they are not needed in this assembly. |

Figure 2. |

| Step 3. Cover the side of the tube opposite the screw head with electrical tape. This will prevent the sensor terminals from shorting to the tube. |

Figure 3. |

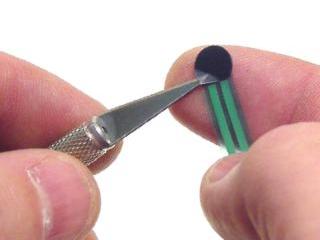

| Step 4. Use an exacto knife to carefully peel away the CLEAR plastic piece covering the black adhesive. Be very careful doing this! If not done carefully the sensor can be damaged! |

Figure 4. |

| Step 5. Stick the adhesive side of the sensor to the end of the leg as shown, then carefully bend the wires to lay along the leg. Make sure you don't try to bend the sensor tail too sharply! Secure the sensor tail and wires to the leg as shown using electrical tape. Note, the sensor should be centered on the flat of the aluminum hub. |

Figure 5. |

| Step 6. Peel an adhesive-coated bumper off of the paper, and stick it firmly on the end of the leg as shown. Note, this should be centered precisely on top of the FSR. We chose clear rubber bumpers to make this easier. |

Figure 6. |

| Step 7. Attach a nylon wire tie to the wires. Attach an ohm meter to the FSR wires. Gently slide the rubber foot over the sensor and tip of the foot. Push it on till the meter reads some resistance, then carefully and slowly work the rubber end cap in the opposite direction just till the meter reads open. If you are unable to get the meter to read open (infinite resistance) then you may need to adjust the wire tie, or the bend on the sensor in Step 5. After proper set up the sensor should read open until it makes contact with the ground. On a moving robot, the rubber end cap holds the sensor in place even with significant lateral loading. Also the sensor will return to an open even after being under load for a long time. This simple robust design will easily handle the weight of our AH3-R robot. |

Figure 7. |

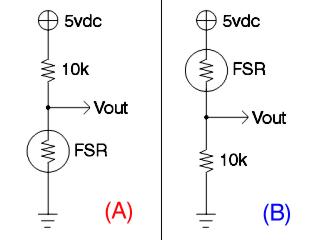

| Step 8. There are many ways to use the FSR, but the simplest is to just use a 10k pull-up resistor. Using setup "A" shown in Figure 8, we were able to get the following response, illustrated by the red line in the Sensor Output Chart. Using setup "B" shown in Figure 8, we were able to get the following response, illustrated by the blue line in the Sensor Output Chart. |

Figure 8. |

| Sensor Output Chart. Refer to the following chart for expected pressure vs voltage values.

|

|