AL5C Arm Assembly Instructions Rev. 1

| AL5C Arm Assembly Instructions Rev. 1.

Updated 10/07/2009. Safety first! Wear eye protection and never touch a powered robot! Note: Loctite or thread locks can be used on the construction of the aluminum components. However, don't use them with Lexan, as they are not necessary and may cause damage. |

Image of complete arm. |

||||||||||||||||

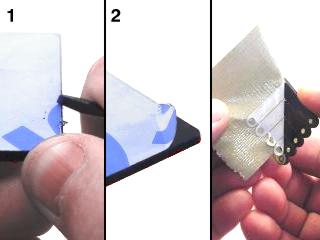

| Lexan Preparation. The lexan pieces have a protective covering that needs to be removed before assembly. When the laser cuts, the covering melts into the cut edge which can make removal difficult. If you gently scrape the cut edge with a flat blade screwdriver, the covering can easily be lifted and peeled off. On smaller pieces the coverings can be more difficult to remove. If you have trouble you can gently scrape the cut edge, then use duct tape to lift the covering off. For further information on lexan, see this page. |

Lexan Preparation. |

||||||||||||||||

| Step 1. Attach two of the tubing connector hubs to the "C" and large "C" brackets, using four 2-56 x .250 screws and 2-56 nuts.

|

Figure 1. |

||||||||||||||||

| Step 2. Connect the hubs to the 2.25" tube using two 4-40 x .250" screws.

|

Figure 2. |

||||||||||||||||

| Step 3. Install the mechanical dampening panels as shown. Use four #2 tapping screws. |

Figure 3. |

||||||||||||||||

| Step 4. Insert the 4-40 x .5" Phillips head screw through the hole in the multi-purpose bracket as shown. Secure with a steel nut.

|

Figure 4. |

||||||||||||||||

| Step 5. Slide the large "C" bracket end of the bracket assembly over the screw as shown, and secure with a nylon insert lock nut. The amount of friction can be adjusted by tightening or loosening the lock nut. Start with the nut loose, and if the arm seems to wobble a bit, you can tighten this joint to correct the wobble. Caution - don't over-tighten this! If the arm is operated with the mechanical dampeners too tight, the servo WILL heat up and CAN be damaged!

|

Figure 5. |

||||||||||||||||

| Step 6. Figure 6 show a typical mega-size servo with its default servo horn at center position. You will need to replace this black servo horn with the round nylon servo horn. Remove the servo horn screw, being careful to not rotate the servo horn itself. Pull the servo horn off, then press the nylon servo horn in place, as close to the alignment shown as possible. Replace the servo horn screw. Make sure your servo looks like the image. The arrows in the image point to the screw holes you will use. |

Figure 6. |

||||||||||||||||

| Step 7. Attach the HS-755HB servo to the base bracket as shown using the 3mm hardware; follow the diagram below. Use two #2 x 1/4" tapping screws to secure the bracket to the servo horn. Route the shoulder servo wires underneath the servo. Plug the servo into channel 1 on the SSC-32. Carefully rotate the base to an extreme, and use a wire tie to take up the slack in the servo cable.

|

Figure 7. |

||||||||||||||||

| Step 8. Attach two of the tubing connector hubs to the short side of the "L" brackets, using four 2-56 x .250 screws and 2-56 nuts.

|

Figure 8. |

||||||||||||||||

| Step 9. Connect the hubs to the 3.38" tube using two 4-40 x .250" screws. Tighten these down tightly.

|

Figure 9. |

||||||||||||||||

| Step 10. Attach the tubing structure to two Multi-Purpose brackets as shown, using four 2-56 x .250 screws and 2-56 nuts.

|

Figure 10. |

||||||||||||||||

| Step 11. Insert the 4-40 x .5" Phillips head screw through the hole in the multi-purpose bracket as shown. Secure with a steel nut.

|

Figure 11. |

||||||||||||||||

| Step 12. Slide the screw on the forearm assembly through the dampening discs as shown, and secure with a nylon insert lock nut. The amount of friction can be adjusted by tightening or loosening the lock nut. Start with the nut loose, and if the arm seems to wobble a bit, you can tighten this joint to correct the wobble. Caution - don't over-tighten this! If the arm is operated with the mechanical dampeners too tight, the servo WILL heat up and CAN be damaged!

|

Figure 12. |

||||||||||||||||

| Step 13. Figure 13 illustrates a typical standard-size servo with its output horn (the round white part) at center position. Make sure your servo looks like the image. The arrows in the image point to the screw holes you will use. Step 14.

|

Figure 13. |

||||||||||||||||

Figure 14. |

|||||||||||||||||

| Step 15. Add a 6" servo extender cable to the elbow servo. Plug the cable in to channel 2 on the SSC-32. |

Figure 15. |

||||||||||||||||

| Step 16. Attach the Little Gripper connector to the short "C" bracket using two 2-56 x .250" screws and 2-56 nuts.

|

Figure 16. |

||||||||||||||||

| Step 17. Attach the short "C" bracket to the other Multi-purpose bracket as shown.

|

Figure 17-2. |

||||||||||||||||

| Step 18. Attach the HS-475HB wrist servo to the bracket as shown using the 3mm hardware; follow the diagram below. Use two #2 x 1/4" tapping screws to secure the bracket to the servo horn. Route the shoulder servo wires over the servo.

|

Figure 18. |

||||||||||||||||

| Step 19. Attach the Little Grip to the lexan as shown, using three 4-40 x .375" button head screws and acorn locking nuts. Only three screws are used (shown in the image) as the body of the gripper servo is in the way for the fourth. Make sure the HS-422 servo is aligned to mid-position, and the gripper is halfway open. Now the servo and

gripper will be aligned correctly. Remove the servo screw and horn. Slide the servo into the gripper from the bottom. You may need to wiggle it

a bit to get it seated properly. Use the servo screw to attach the servo. Tighten this down, but then unscrew it half a turn. Too much friction

can bind the servo.

|

Figure 19. |

||||||||||||||||

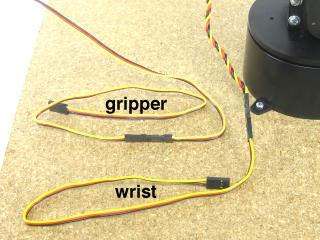

| Step 20. Add 12" servo extender cables to the gripper and wrist servos. |

Figure 20. |

||||||||||||||||

| Step 21. Carefully bend the wrist servo back as far as it will go, and use wire ties to secure the servo cables as shown. Make sure to leave slack in the gripper servo cable, don't pull it too tight. |

Figure 21. |

||||||||||||||||

| Step 22. Carefully stretch the arm forward as far as it will go, and use wire ties to secure the servo cables as shown. Make sure to leave slack in the cables, don't pull them too tight. Plug the servos in according to Table 22.

|

Figure 22. |

||||||||||||||||

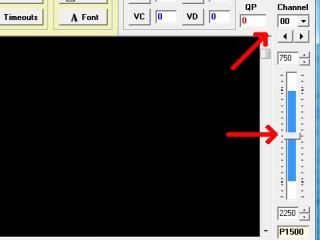

| Step 23. As in the Base Assembly Instructions, we'll use LynxTerm to test the servos and confirm that they're all plugged into the proper channels. If not done before, download and install LynxTerm. Connect the SSC-32 to the serial port and apply power. The green LED should light and stay on until it receives a valid serial command. Run the LynxTerm program. If LynxTerm cannot connect, please consult the serial and USB-to-serial troubleshooting guide. Step 24. |

|

||||||||||||||||

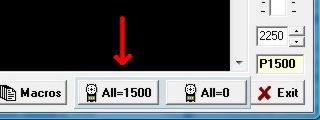

| Step 25. Click on the "All = 1500" button in LynxTerm. This will command the servos to hold center position. Your arm should look like Figure 25. If any joint is off by more than 15°, then you may have made an error in assembly.

|

|

||||||||||||||||

| Step 26. To use the RIOS Arm control software, you need to make one minor modification. Remove the servo horn screw from the elbow servo. Pull the servo horn off the servo, lift the arm two 'clicks' (30°) at the elbow and reattach the servo horn and screw. Note, the Hitec spline has 24 grooves, so each groove is 15°. |

Figure 26. |

||||||||||||||||

| Step 27. At this point the arms is assembled and tested using LynxTerm. Now we need to install RIOS and calibrate the arm to the software. Use the RIOS Help File to calibrate and use the arm. Install RIOS, following the on-screen installation prompts. The serial number is on the back of the CD sleeve. Use the RIOS Help File to calibrate and use the arm, following Steps 1-7. When you get to Step 8 in the help file, please use the following instructions instead. Please take the time to do an accurate calibration. The performance of the arm will only be as good as the calibration. If the on screen virtual arm does not match the real arm this is a sign of an inaccurate calibration. After calibration please study the RIOS manual carefully to learn how to store and playback sequences for the arm. |

|

||||||||||||||||

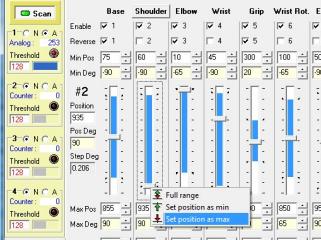

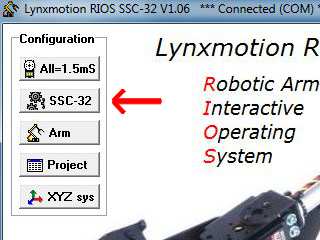

| Step 28. To calibrate the arm's Shoulder servo, click the "SSC-32" button. |

|

||||||||||||||||

| Step 29. Start the servo configuration with the Shoulder, servo #2. Move the shoulder slider up to move the shoulder forward so that it looks like Figure 29-2. Set the Min Deg angle -90°. Right click on the slider to set this as the Min Position. Now the servo will not go past this value, and the program now knows this value is exactly 90° from centered. Now move the slider down to move the shoulder backward so that it looks like Figure 29-3. Set the Max Deg angle to 45°. Right click on the slider to set this as the Max Position. Now the servo will not go past this value, and the program now knows this value is exactly 45° from centered. |

|

||||||||||||||||

|

|

|

||||||||||||||||

| Step 30. To connect springs for load-balancing, replace the servo attachment hardware in the locations shown, following the diagrams below. Hook the springs together after they're secured.

|

Figure 30. |

||||||||||||||||

| Step

31. The arm assembly is complete. The next step is to read and study the RIOS users guide. It is accessible by clicking on the help icon on the main screen or by navigating to the install directory (c:\Program Files\RIOS_SSC-32\) and opening the Help.pdf file. This manual explains in great detail how to use the arm. The arm is robust mechanically, but the servos can be damaged by improper use. An example would be if the arm was told to move to an unobtainable position, like the surface the arm is mounted to, or by crashing the arm into itself, or other objects. The elbow servo is the most vulnerable because it holds the entire weight of the forearm. Load balancing springs should be added to reduce some of this load. People do not like holding heavy objects with their arms outstretched in front of them. Servo based robot arms don't like it much either. Remember, the most important rule for servo based robot arms: Park the arm when not in motion! When it's moving or at rest it's usually ok. When it's holding an object it should do so for the minimum amount of time required to do the job. You can always touch the servo case to see if it's getting hot. |

Figure 31. |

||||||||||||||||