| Pneumatic Syringe Assembly Instructions.

Updated 10/12/2010

Safety first! Wear eye protection and never touch a powered robot!

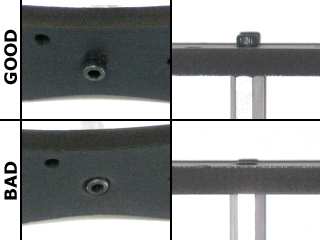

Note: Do not use Loctite or thread locks on the assembly. They are not necessary and may cause damage to the

PVC. Remember that the PVC parts DO have a

definite good and a bad side. Try to keep the good sides facing the outside.

|

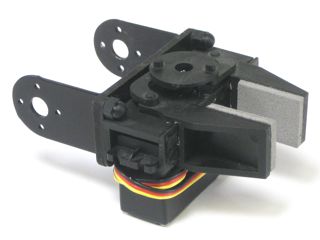

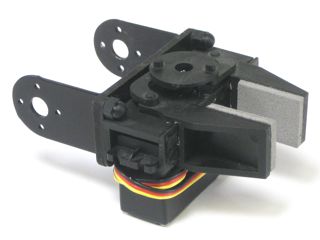

Image of completed assembly. |

| |

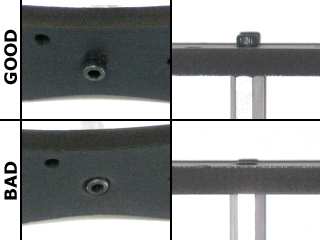

IMPORTANT!

DO NOT overtighten screws on the PVC parts! The PVC will compress and will become weaker as a result! |

Example image. |

| |

Step

1.

The PVC parts are brushed off before they are packaged, however, there may still be residue on the parts. Just take a damp rag and wipe the parts clean. |

Figure 1. |

| |

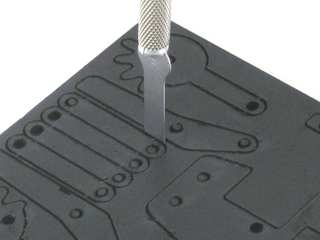

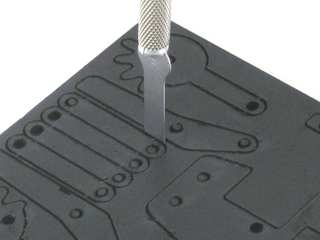

| Step 2. The PVC parts need to be carefully cut out of the panel. A thin, flat blade exacto knife will be very helpful when removing the parts. Simply cut through the tabs to remove the parts.

The tabs may leave some rough edges. Take some sandpaper and rub these edges smooth. |

Figure 2. |

|

Step 3.

Take the two large PVC parts and insert the tabbed part into the slotted one. This should make an "L" shape with the engraved writing on the inside.

Run a bead of superglue down the seam where the two parts meet. Let this dry for 3-5 minutes before proceeding. |

Figure 3. |

| |

Step 4.

Attatch the 4-40 x 1.0" screw and two nylon insert locknuts as shown in the picture. Note, there should be a small space between the two nuts.

| 1 x |

2 x |

|

|

|

Figure 4.

|

| |

Step

5.

Remove the screw in the center of the servo horn (the white plastic part) from the servo and remove the servo horn. Save this screw! You will need it later.

Install the servo into the base as shown using two 4-40 x .5" screws and 4-40 nuts.

Figure 5-1.

|

Figure 5-2. |

|

|

|

Step

6.

Attach the remaining two PVC parts to the syringe using zip ties, exactly as shown. Take care to not tighten these down too much, as it will cause the cylinder to distort and not form a good seal with the plunger.

Also note, it is very important that the zip tie on the plunger needs to be aligned as shown in the picture or it will collide with the red servo horn that is added later. |

Figure 6. |

| |

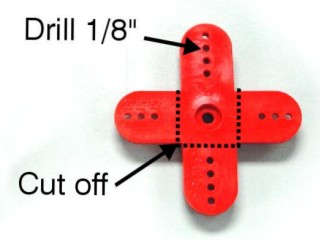

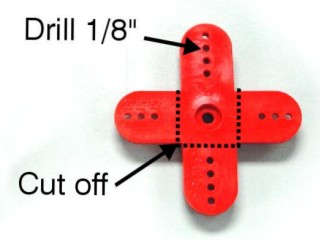

Step 7.

Drill out the hole shown in Figure 7-2 with a .125" drill bit. This does not require any powertools, as it can be done easily by hand as shown below.

Afterwards, cut off the three other legs off the servo horn. We used a pair of angle cutters in house.

Figure 7-1.

|

Figure 7-2.

|

| |

Step

8.

Attach the servo horn to the small PVC part using a 4-40 x .625" screw and two nylon insert lock nuts.

Be sure to keep the assembly loose enough to allow easy movement.

| 1 x |

2 x |

|

|

|

Figure 8.

|

|

Step 9.

Note, if you would like to mount the vaccum assembly to something, such as a piece of wood, do that BEFORE attaching the syringe to the holder as the syringe will block one of the mounting holes.

Attach the syringe assembly to the holder using a 4-40 nylon insert lock nut and the screw you saved from step 5. Be sure the red servo horn points straight up when the servo is centered. This will ensure that the maximum range can be achieved with your assembly.

| 1 x |

|

|

|

|

Figure 9. |

| |

Step

10.

Attach the elbow fitting to the long C bracket using two large washers and nut. Be sure to align the fitting as shown.

| 1 x |

2 x |

|

|

|

Figure 10. |

| |

Step 11.

Remove the old gripper, short C bracket and the gripper servo (shown in Figure 11). Remember to leave the ball bearing in place and to save the two .25" tapping screws. You will need the screws to attach the new gripper. |

Figure 11.

|

| |

Step

12.

Attach the long C bracket onto the end of the arm, where the old gripper assembly was, as shown in Figure 12, using the screws from step 11.

| 2 x |

|

|

|

|

Figure 12.

|

|

Step 13.

Slide the suction cup over the outside of the elbow and slide the tubing over the other end. Secure the tubing to the arm with a zip tie as shown below.

Note, DO NOT overtighten the zip tie as this will compress the tubing, not allowing air to move through.

Figure 13-1.

|

Figure 13-2. |

| |

Step 14.

Slide the other side of the tubing onto the end of the syringe. Plug the vaccum servo into the same servo pin as the gripper, which is pin 4 by default. |

Figure 14. |

| |