SES-PRO Robotic Arm UI Guide

Before proceeding with the guide, it is important to note the following:

It's a good thing to practice with the software without an Arm connected, that way you can learn safely. | ||

| Pressing the i "Information" icon in the software will bring you to the SES-PRO Robotic Arm UI page. | ||

IMPORTANT | ||

Payload Considerations | ||

| ||

Emergency | ||

| Before using the arm, it is important that a user know what to do when an issue or emergency arises where the arm must be stopped quickly. The following emergency options are available based on severity: | ||

Halt (and hold) This will stop every joints and hold them in their last recorded angular positions. The corresponding command is #254H<cr>. | ||

Limp All joints will go limp which mean there will be nothing avoiding them to turn freely (potentially causing the arm to fall). The high gear ratio of the strain wave gearing does mean there is some (low) level of resistant to rotation, but the gears and motor are nto "locked" and as such, the arm may fall. The corresponding command is #254L<cr>. | ||

Software E-Stop The E-stop button within the software sets all joints to limp, this can possibly cause the arm to fall. | ||

Power Supply E-Stop A hardware E-stop (push to cut power) button is located on the power supply which will cut electricity to all actuators. Similar to a limp command, this can possibly cause the arm to fall. To reset this button, rotate the red "mushroom" in the direction indicated by the white arrows and it will spring out. | ||

Robotic Arm | ||

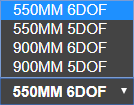

Model The software currently supports the following Lynxmotion PRO Arms:

In practice, each 5DoF arm has joint 4 at a fixed angle, otherwise the arms are identical to the 6DoF. Users can always purchase the missing actuator to upgrade to a 6DoF. | ||

COM Port The first joint at the base (J1) must be connected via USB to a computer running the sofware. No other joints should have a USB connection. A USB 3.0 port or higher on the computer is suggested, as the lower communication speeds fo USB 2.0 or 1.0 may impede communication and cause unecessary delay or issues. | ||

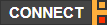

Connect / Disconnect Once the COM port has been selection, the CONNECT button can be pressed, and once a servo has been found, the light next to it will go from red to green. | ||

Gripper | ||

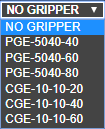

Model The software currently supports two models of Lynxmotion PRO compatible grippers based on DH Robots' PGE-50-40 and CGE-10-10 electric grippers. The Lynxmotion kits include hardware to mount the fingers in multiple different offsets for smaller or larger objects. In the sequencer, the position of the fingers for each gripper are included in the sequencer as G. | ||

| ||

COM Port Choose the appropriate COM port to which the gripper is connected (via its own USB cable). If you are not certain, you can check Windows -> Device Manager | ||

Baudrate The DH Robotics grippers provide the option to change the baud rate, though the default is 115200. If the gripper is configured by the user to a different baud rate, it is important to select the corresponding baud rate in the software. | ||

Connect Pressing CONNECT establishes a connection to the gripper and goes through the initilization process once, opening the gripper fully. Once connection has been established, the light next to the button will go from red to green. | ||

Initialize Initializing the gripper opens it fully. This is available should the user encounter issues with positioning and need to re-zero the fingers.

| ||

Position

| ||

Speed The speed of motion can be adjusted either via the plus or minus buttons or entering a value between 0 and 100 and pressing enter. | ||

Force The maximum force exerted by the gripper can be adjusted either via the plus or minus buttons or entering a value between 0 and 100 and pressing enter. | ||

Open / Close These are shortcut buttons to either fully open or fully close the gripper. | ||

Sequencer The sequencer displays the gripper position as joint G. Ex: #GP1000 HINT: If you want the gripper to open or close on an object only at the end of a motion, create a separate frame where only G moves. | ||

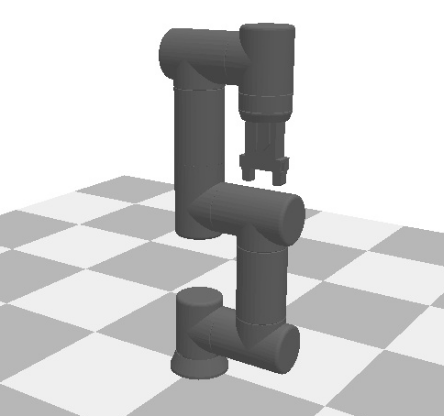

3D Model | ||

The 3D model of the arm is shown as reference at all times. The display also includes a virtual plane to denote the X-Y plane. The model updates based on the selection of the arm, gripper and finger configuration. | ||

View Controls Zoom: Shift + Middle Scroll Rotate: Shift + Middle Mouse Pan: None | ||

Manual Move | ||

Joints Control (angular) In Joints mode, the user can control the angle of each joint.

| ||

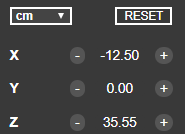

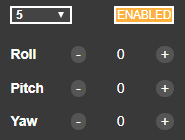

Coordinates Control In coordinate control the user can control the cartesian position of the end effector | ||

End Effector Lock The orientation of the end effector can be locked with the "ENABLED" button. | ||

Direct Command | ||

This section allow the user to send commands using the LSS-PRO Communication Protocol directly if required. A few things to keep in mind when using this:

| ||

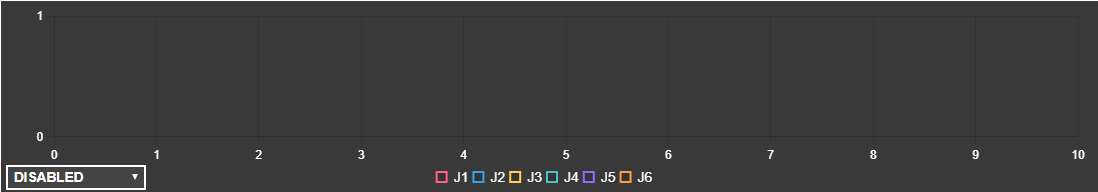

Telemetry | ||

Data to Display Various telemetry data can be retrieved from each actuators / joints, here is what the software support:

| ||

Display / Hide At the bottom of the graphics you will find squares to activate / deactivate the desired actuator / joint to be displayed in the graph. | ||

Sequencer | ||

Sequence

| ||

Sequence Selector

| ||

Add

| ||

Substract

| ||

Copy

| ||

Save

| ||

Open

| ||

Delete

| ||

| Frames | ||

Add

| ||

Sequence Selector

| ||

Record

| ||

Remove

| ||

Copy

| ||

Paste

| ||

Invert

| ||

Frame

| ||

Frame Position Moving your cursor to the upper part of the frame will display a "hand" and then you can drag the frame into a new position. | ||

Starting Frame

| ||

Loop

| ||

Manual Edit Time, angles, gripper | ||

Zoom

| ||