LSS - Mechanical

Version 27.5 by Eric Nantel on 2019/01/29 15:31

Table of Contents

Features

With the LSS (Lynxmotion Smart Servo) we incorporated some features which make sense for Robotic applications. Bellow are some of the main features present on the LSS.

Driving Horn | |

| The driven horn is connected to the output shaft of the final gear in the gear down within the servo. This output shaft has a specific cross section called a “spline” (the “male” version of the spline), and the driven horn has the mating “female” spline. The driven horn is held in place using a 3mm machine screw. |

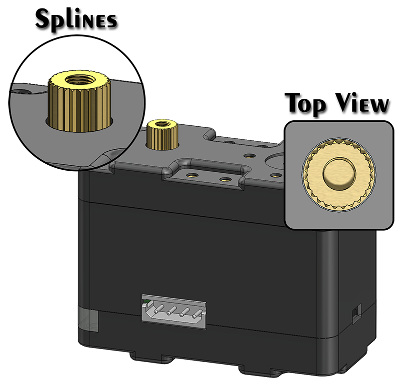

Spline | |

| The spline allows the driven horn to be connected to the output shaft so that it rotates with the shaft. There are many different spline cross sections, and in order to ensure the a horn can fit onto the output shaft of the servo, it must have the matching / identical spline. |

Idler Horn | |

| The idler horn is not driven and allows a free-spinning horn to be placed in one of three locations on the servo. The idler horn sub-assembly consists of a spacer, a ball bearing and the idler horn itself. The idler horn is held in place using a 3mm machine screw. |

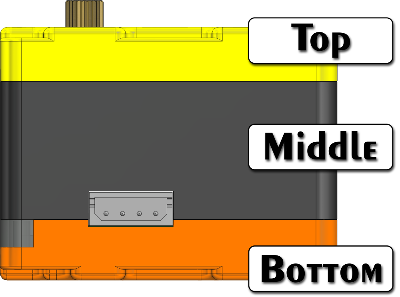

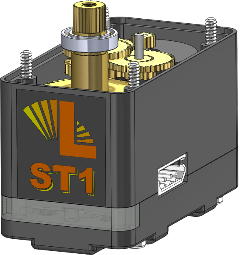

Case | |

| The black plastic case which forms the body of the servo is made up of three sections: the bottom (opposite the driven horn), the center and the top. The case components are made of injection-molded ABS plastic. There are four screws which hold together the case which are not meant to be opened. |

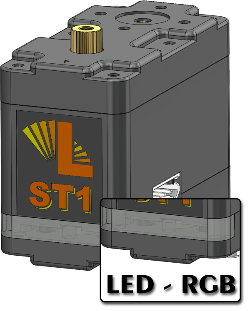

LED Bar | |

| The LED bar covers an internal RGB LED and allows the user to get visual feedback of the status / configuration of the servo |

Connector | |

| There are two four-pin connectors located on either side of the servo. The female pins are GND (0V), V+ (6V to 12V), Rx (receive pin) and Tx (transmit pin). The order of the connector pins is reversed from one side of the servo to the other. In order to receive or send a command / signal only one side needs to be connected. The other connector need only be used when adding another servo to the chain. |

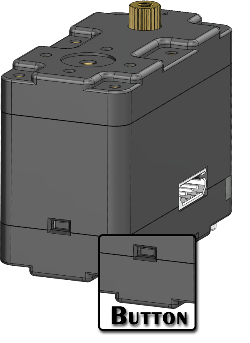

Button | |

| The small button located at the rear of the servo is meant to allow the user to change the servo’s settings / configurations. The button is recessed so it is not pressed accidentally, nor is it meant to be used often, as the software interface allows for full control over these settings as well. Do not press the button too hard. |

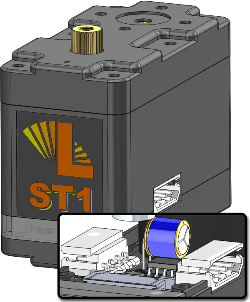

Gearing | |

| The internal gearing within the servo is located inside the top part of the case and has the effect of reducing the motor’s RPM while increasing the torque. The gear train is made up of a variety of metal spur gears. |

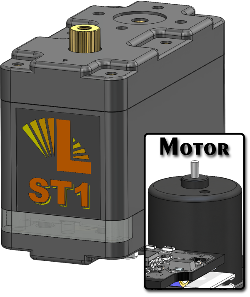

Motor | |

| The brushed DC motor is located within the central part of the case. The motor used in the high torque servo is coreless, while the motor used in the standard and high speed servos is cored. |

Electronics | |

The electronics inside the servo include the following:

| |

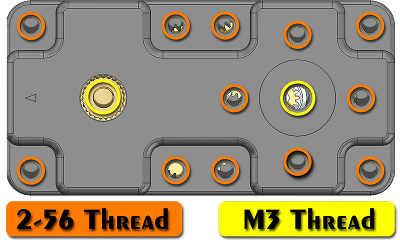

Threaded Inserts | |

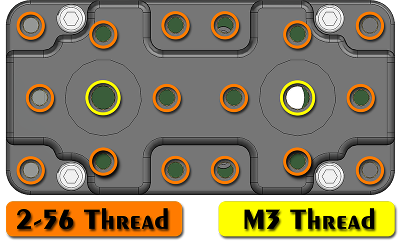

| The top case of the servo includes 12x 2-56 threaded inserts plus one M3 threaded insert located at the center of the SES pattern as well as the M3 threaded spline shaft. |

| The bottom case of the servo includes 16x 2-56 threaded inserts plus two M3 threaded inserts located at the center of the SES pattern. |

| IMPORTANT NOTE: ONLY USE THE 2-56 x 14” SCREWS PROVIDED. LONGER SCREWS CAN AND WILL CAUSE DAMAGE TO THE SERVO. |

SES Pattern

The SES mounting pattern is based on two holes which are used for mounting objects to a Hitec standard servo horn such as the Hitec HS-422. The mounting pattern involves:

|

|

| Newer brackets have four additional holes (for a total of eight holes) spaced at 45 degrees to allow for easy mounting. |

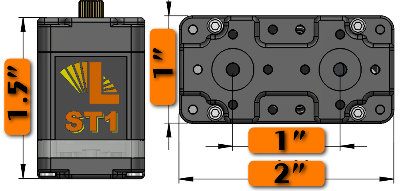

Dimensions

| |

|